Need some advice about modifying wing for retracts.

#1

Thread Starter

Join Date: Jun 2018

Posts: 25

Likes: 0

Received 0 Likes

on

0 Posts

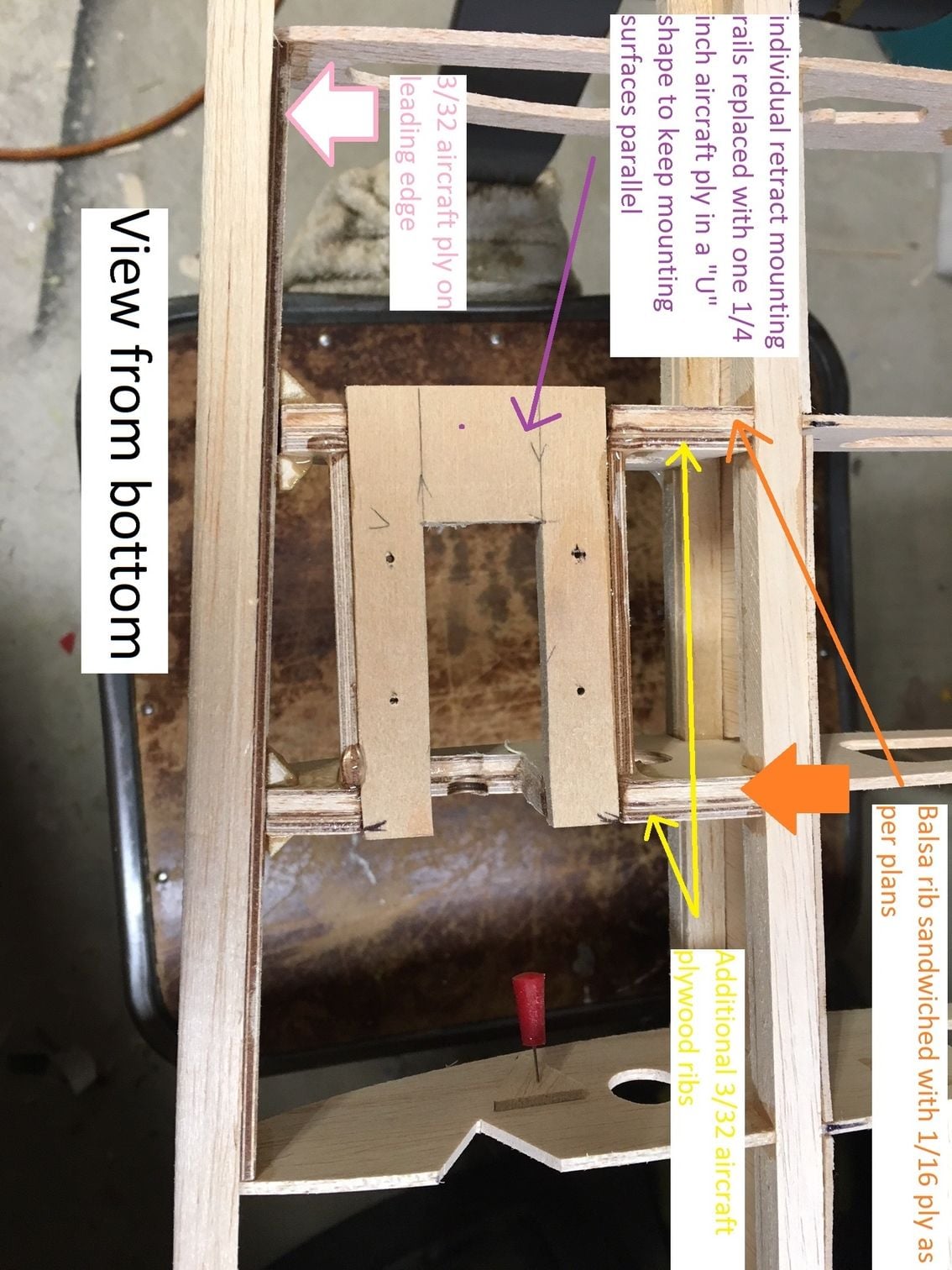

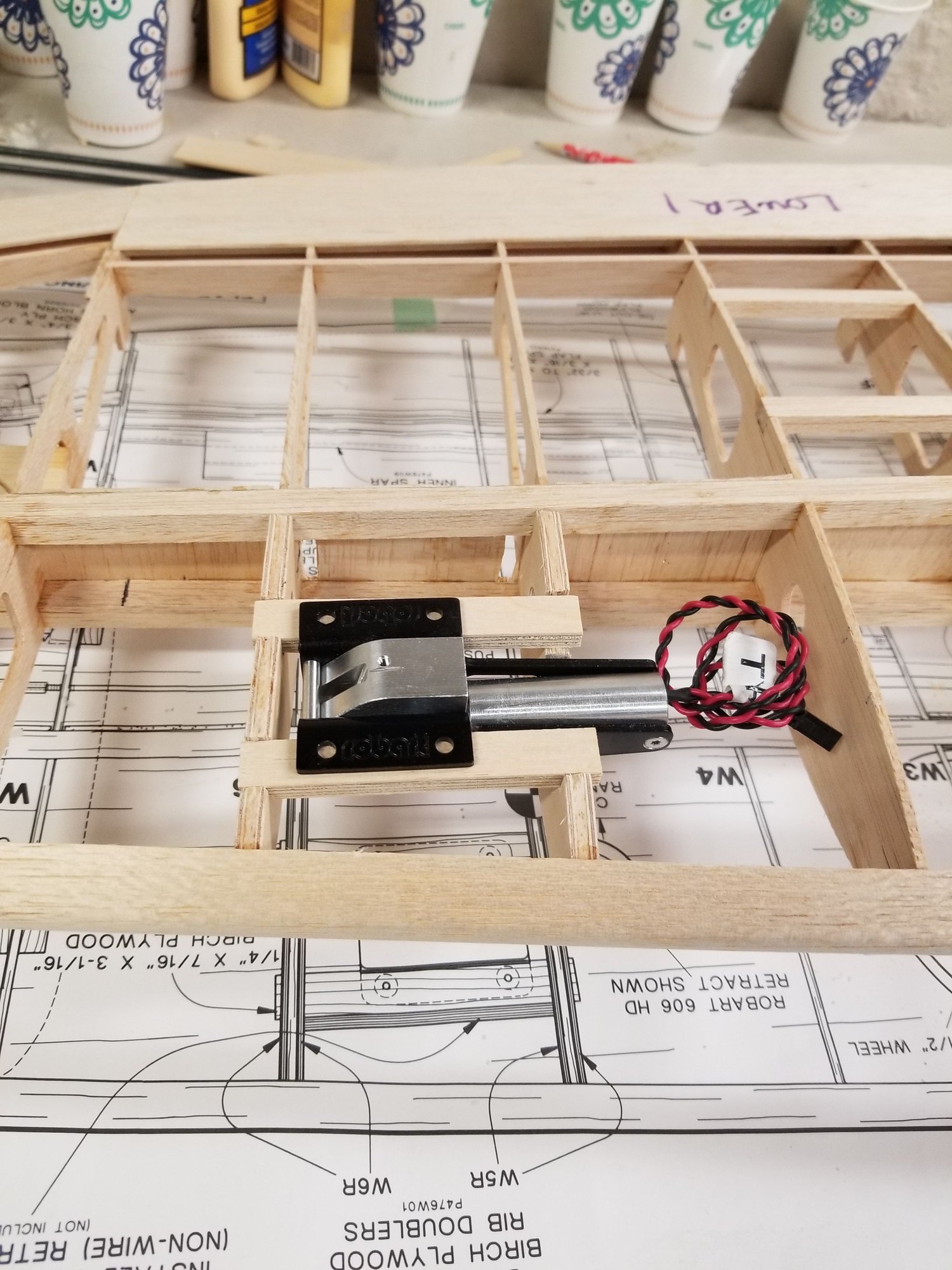

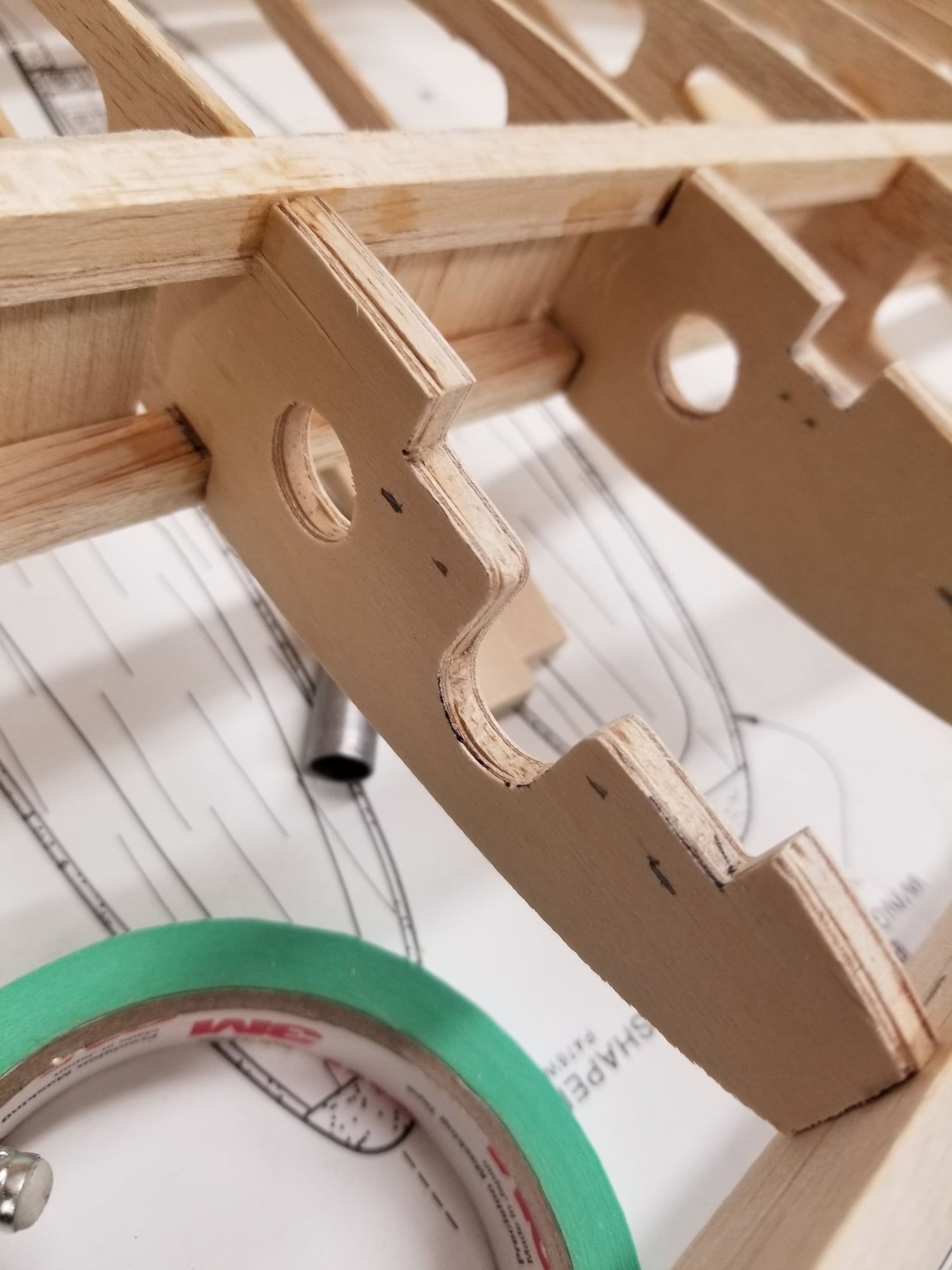

I have a TF p47 and ro art talked me I to 551 roses because I fly off grass field. So trying to make them fit. And it looks like they will. Need to know if my wing ribs are too cut up??

551rse was hanging to high. Any suggestions ease help I need it!!!

#2

My Feedback: (3)

If you have any doubt then soak the ribs and doublers for the retracts with thin CA glue to toughen the wood up. Then use epoxy with 3/4 ounce fiberglass cloth or tape to laminate each side and blend to the wing spar and spar webbing. That will be more than enough to toughen the ribs up. In addition the wing sheeting will help further if you cover the top first and then add a square of fiberglass to the inside overlapping the ribs, leading edge and spar by about 1/4 inch. You can use carbon fiber instead like a 6K cloth. You can also use filler like micro balloons or milled glass fiber to make a paste that will help you fillet the edges and help the cloth lay up the corner.

Hope that helps, keep posting pics of your build!

Hope that helps, keep posting pics of your build!

#6

My Feedback: (8)

Make new rails that are long enough to extend out at least a quarter inch on the other side of the ribs in order that you can double the amount of gussets to help hold them in the wing on those less than graceful landings we all have sooner or later. Gussets under the rails on both sides of the wing ribs.

#7

My Feedback: (34)

Being that you can work from the top of the wing, try gluing in some Carbon Fiber and run it along both the landing gear plate and the ribs, all the way to the leading edge. The rear mounting fixture will rotate in a less than desirable landing, but the leading (front) plate will rip outward and backward. Just my $.02.

#8

Banned

I'd run the ply ribs all the way to the TE. I'd change all ribs to the root to ply. And I'd also use ply for the sheer web from the gear to the root.

And NOT lite ply. I'd use quality Birch Ply all the way.

And NOT lite ply. I'd use quality Birch Ply all the way.

#11

My Feedback: (3)

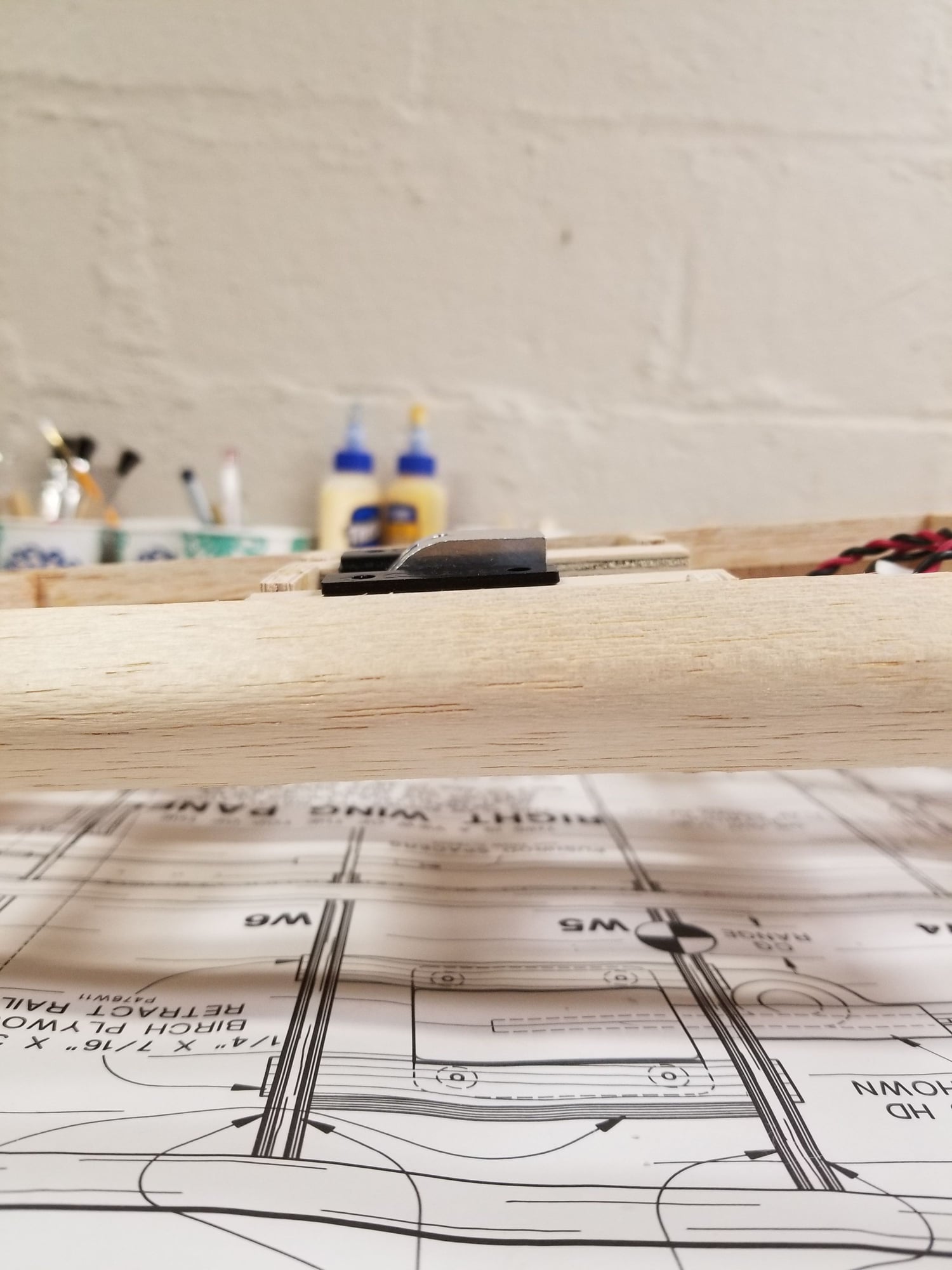

The rails are not capped I see. You should have a complete rib all around the rails. I’d add a filler piece of ply and then run some thin ply sheet or some carbon fiber along the faces each side of the rib. The torque from the retract will want to yank out the rails as well as twist them.

#15

My Feedback: (3)

Good question, either works but the blind nuts have a tendency of stripping and having issues, for some people. If you use wood screws then in the event of a hard landing the screw can tear out before damage is done to the wing mounts and ribs. So I'd suggest for a model of this size just go with wood screws, full length, through the plywood. Also, use thin CA in the threaded screw holes and toughen them up. Its also easier to align the holes and not mess with blind nuts.

If you can just add a strip per side of triangle stock behind the plywood retract plate. It serves to spread the load and increase the bonded surface area but its still light weight. Do it where is makes sense to tie into ribs.

If you can just add a strip per side of triangle stock behind the plywood retract plate. It serves to spread the load and increase the bonded surface area but its still light weight. Do it where is makes sense to tie into ribs.

#17

I would suggest using hardwood to make the tri-stock gussets as using balsa tri-stock in this area will not add much strength. Add 3 ounce glass cloth to the entire gear bay area overlapping all rib and gear mounts once the sheeting is completed to tie everything together .

#20

My Feedback: (9)

YOU HAVE ply on both sides of the ribs that's good. I would have run the extra ply you added to the TE only because as is it creates a stress concentration just past the main spar, but what you have is fine. I would toss the plywood in favor of hard wood, i'm quickly running out of my white maple stock and have not found a new source yet. I assume I will have to buy furniture wood and cut it down from now on. the reason ply is a bad idea on grass is it is only as strong as the glue between the layers of wood. with ply every time I have a hard landing I pull the lg and soak the ply w ca.

ply moves when its stressed, at first it moves a little not enough to cause problems but every time it flexes it moves till something stops it. that means it slowly degrades until it fails. usually the failure is with the veneer layer still attached to the airplane, weather it be gussets, or fiberglass it leaves ply there to show that the added stuff you added did not fail it was the glue between the planes of the ply. then lets look at the screws blind nuts vs sheet metal screws. blind nuts over time will actually compress the wood under them (nobody sells marine ply anymore). I have had good luck with ply and even lt ply with sheet metal screws if I pull the screws and ca in them after everything is set up. but if you prang it good they may require a flood of ca where the layers are exposed (that includes in the screw holes)

lastly you want to make the ledge the front mount goes on 1/8 lower (with the wing upside down) to cant the lg leg forward without changing where it retracts to in the wing.

hope this helps

Joe

ply moves when its stressed, at first it moves a little not enough to cause problems but every time it flexes it moves till something stops it. that means it slowly degrades until it fails. usually the failure is with the veneer layer still attached to the airplane, weather it be gussets, or fiberglass it leaves ply there to show that the added stuff you added did not fail it was the glue between the planes of the ply. then lets look at the screws blind nuts vs sheet metal screws. blind nuts over time will actually compress the wood under them (nobody sells marine ply anymore). I have had good luck with ply and even lt ply with sheet metal screws if I pull the screws and ca in them after everything is set up. but if you prang it good they may require a flood of ca where the layers are exposed (that includes in the screw holes)

lastly you want to make the ledge the front mount goes on 1/8 lower (with the wing upside down) to cant the lg leg forward without changing where it retracts to in the wing.

hope this helps

Joe